The Nitrogen High

Sometime we experience things on our jobs that shake us up a little. This story describes my experience with a nitrogen high,

.

The Nitrogen High

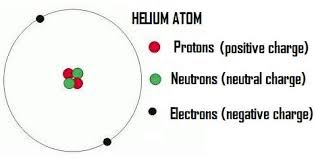

In 1967, I was Plant Engineer for Phillips Petroleum Companies Sherman Helium Plant in Texas near the Oklahoma Panhandle border. The plant extracted Helium from natural gas by cooling the natural gas stream to less than minus 330 degrees Fahrenheit inside equipment in a cold box by virtually liquefying everything in the stream but the helium. The resulting crude helium stream was about 60% helium and 40 percent nitrogen.The crude helium stream was sold to the federal government for storage in their helium conservation program in Amarillo, Texas.

A cold box is full of piping, heat exchangers, and process vessels. They build a steel shell around the equipment, then fill the box with pearlite insulation to hold the cold in. There is very little heat loss to the atmosphere making the process of cooling the natural gas stream to -330 degrees F very efficient.

We had experienced a problem upstream of the cold box that caused the flow to reverse. The flow reversal caused the metal Pall rings inside the separation columns to back flow into the piping and basically clog the piping so the unit would no longer perform’

These are the metal Pall rings that got into the cold box piping and clogged it when the cold box was accidentally back flowed.

To solve the problem, we had purged out the piping and internal vessels with nitrogen to clean all the hydrocarbons out and welded flanges on the piping at strategic locations. We installed rupture discs between the flanges and pressured the system with nitrogen until the discs ruptured and the loose Pall rings in the piping flew out of the system flying as much as a mile away.

It has taken a while to get to the meat of this story, but I had to set the stage. We now had the system cleaned out and had built scaffolding 60 feet in the air to refill the separation vessels with new Pall rings. They had been refilled and new hold down plates had been installed to insure they would stay in place in the system if back flow ever happened again.

One of my jobs was to climb the scaffolding and get inside the vessels and inspect the Pall rings and hold downs to approve the work before we closed the system up. We were still purging the system with nitrogen so I had to wear an oxygen mask when I entered the vessels, I was inside working and I started feeling a little light headed and then I passed out briefly. When I realized that the oxygen mask must not have sealed on my face properly and I was breathing pure nitrogen, my only thought was to get out of there as fast as possible. I started backing out like a speeding bullet, but I was still very woozy and I couldn’t tell whether I was clear or not, so I kept right on going to the edge of the scaffolding 60 feet off the ground. My knees went off the edge of the scaffolding and I was falling. There was a man on the scaffolding that saw what was happening and he grabbed me until the nitrogen high let go of me and I was able to climb back on to the scaffolding. I had survived another near death incident that day. I thanked the lord for helping me get through that one that night.

I was about 3/4 of the way up the cold box on scaffolding inspecting the newly installed Pall rings and hold down plates when I had the problem with my oxygen mask and started backing out with a nitrogen high and almost fell over the side before the guy caught me

After that incident, I better understood why safety required a man just outside when someone was inside a vessel working. Incidentally, I do not recommend trying the nitrogen high as you don’t get high until you pass out and then only if you recover briefly.

Thanks for reading The Nitrogen High,

Bill